Iran using home-made track switches to expand railways: Report

Iran is no longer in need of importing railroad switches from abroad as a domestic company has mastered the know-how to manufacture the complicated installation inside the country.

A Thursday report by the IRIB News said an unidentified start-up firm operating in the northwestern city of Tabriz has been manufacturing track switch systems which include sensitive blades made of special alloys that are welded using sophisticated technologies.

The report showed technicians designing, welding and testing switches that have already been deployed in the railway system in Iran after obtaining the required safety certificates.

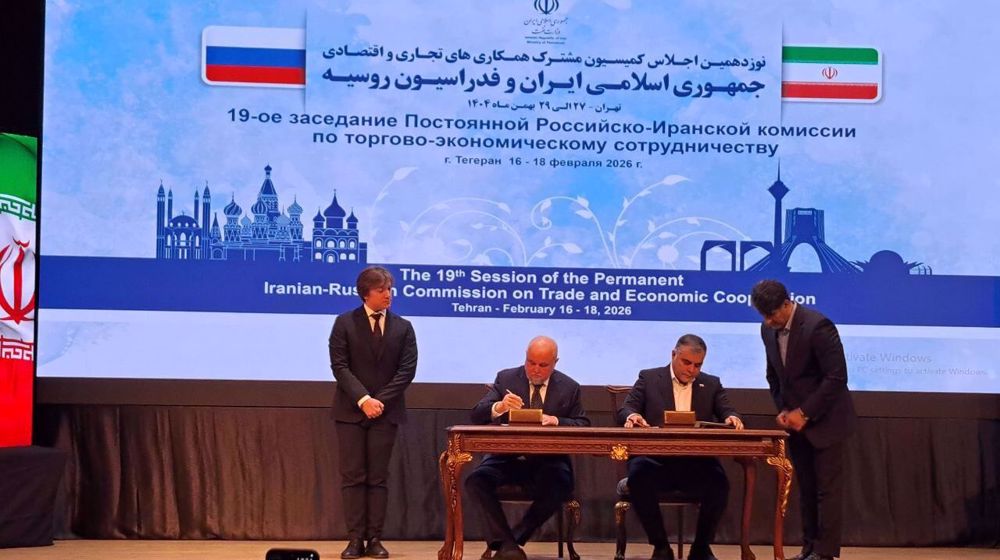

Iran used to spend $20 million a year on imports of track switch, a bulky mechanical structure which enables guiding trains from one track to another.

The IRIB News report said sanctions imposed by the United States and the growing demand for switches in Iran and in neighboring countries encouraged domestic companies to come up with a local solution for the installation.

The government has relied on local steel manufacturers and other companies to advance its ambitious railway development plans.

Iran’s third largest steel producer, the Esfahan Steel Company, has been supplying locally-produced tracks to massive railway projects in the country. Other companies have managed to localize production for brake systems and monoblock wheels required in train manufacturing operation, said the IRIB news.

Iran aims to expand the length of its domestic railway network to 14,000 kilometers by March 2022 when a five-year vision plan comes to its end.

Based on the plan, the railway system in Iran should be able to accommodate 195 million metric tons of freight and 100 million passengers per year.

Pezeshkian condemns ‘savage’ US-Israeli attack on school that killed nearly 90

Islamic Jihad extends 'full solidarity' with Iran following Israeli-American aggression

Leader of the Islamic Revolution martyred in cowardly Israeli-American aggression

Iran to continue acting in self-defense until enemy’s aggression ends: UN envoy

True Promise 4: IRGC launches new waves of missiles at Israeli, American targets

Iran to make Zionist criminals and vile Americans regret their actions: Security chief

Hezbollah, Ansarullah warn US-Israeli aggression on Iran to engulf entire region

Russia strongly condemns US-Israeli aggression on Iran, calls for UNSC meeting

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website